方案

By Technology

公司介绍

八月 14, 2024

Share:

The first cordless electric drill powered by a rechargeable battery was designed and manufactured by BLACK+DECKER® in 1962. Driven by advancements in battery technology, global industrialization and the growth of the do-it-yourself (DIY) movement, the market for battery-powered tools has since exploded.

While conventional cordless handheld tools operate off 12–36 V battery voltage, there is a new and increasing market for tools operating on battery voltages up to 72 V. This is being driven primarily by professional users who require the increased power that such high voltage battery-powered tools can provide. However, these new tools will require advancements in the main subsystems: battery charger, battery/power tree and the motor/motor driver. To address these challenges, onsemi has developed a complete portfolio of solid-state components for the three subsystems.

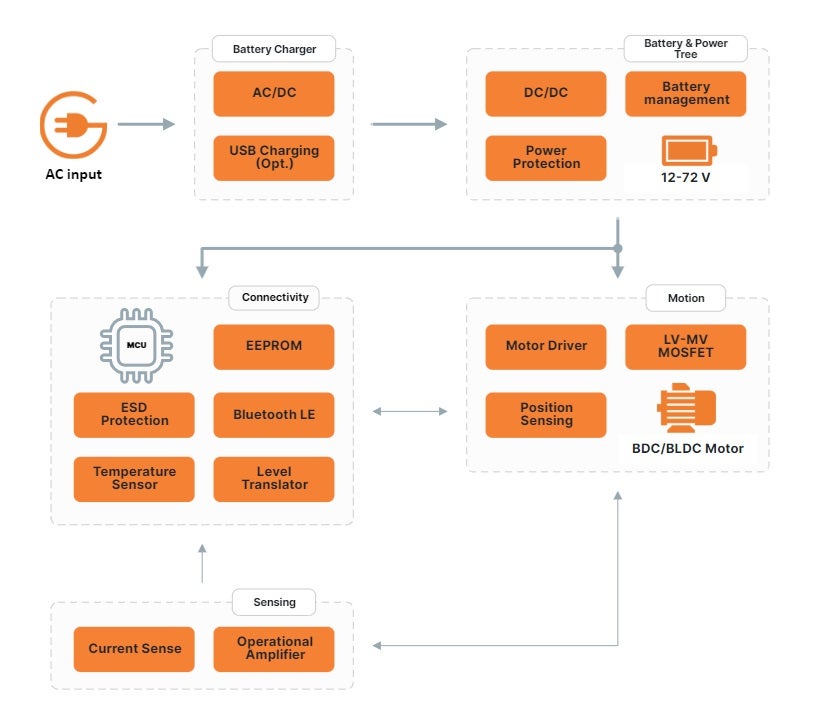

A simplified block diagram detailing the main functions of a battery-powered tool is shown in Figure 1 below.

The functional block diagram shows the three major subsystems that comprise a cordless power tool (protection is a separate category, although not a separate subsystem):

Each of the primary subsystems is discussed in detail below.

The battery charger’s job is to efficiently recharge standby battery packs. It typically does this by converting single phase 115/230 VAC to the specified battery pack voltage. This subsystem consists of an AC/DC converter stage and a safety stage to protect against overcharging and overheating.

Ideal battery chargers are compact, designed for portability and storage and are compatible with standard AC outlets. Today, almost all battery chargers come with some form of power factor correction (PFC) to improve efficiency, reduce harmonic distortion and comply with regulatory standards.

Battery management and power tree are board-based subsystems within power tools. Battery management is like the brain of a battery pack, monitoring and managing battery performance while ensuring it doesn’t operate outside its safety margins. This includes challenges such as overcharging or over-discharging.

The power tree supplies all logic levels and low voltage power rails in the system. The objective is to efficiently deliver all necessary voltages to the other subsystems.

Power tools rely on some kind of battery-powered motor to do their job, with the motor being either a brushed DC (BDC) or a 3-phase brushless DC (BLDC) motor. BLDC motors are rapidly becoming the norm in high-end battery-powered tools by the advantages such as higher efficiency, longer lifespan and quieter operation.

The power stage responsible for driving these motors must fulfill several performance criteria to ensure optimal functionality. These include a compact form factor, high efficiency, dependable operation and internal protection.

Motors require current surges to operate properly, but current surges can also destroy electronic devices and components if they are not properly protected. So, an important part of any cordless tool is protecting the internal electronics.

Another type of threat to internal electronics is electro-static discharge (ESD). Low-level electronics, like controllers, are especially vulnerable to unwanted ESD. Reliable operation and long lifetimes of battery-operated tools cannot happen without adequate internal protection of essential components.

In the battery charger, different topologies are used for AC/DC conversion, PFC and DC/DC step down conversion. The one thing they all have in common in modern battery chargers is their requirement for MOSFET switches.

For use in power tools, MOSFETs must work efficiently under both heavy loads and light loads with low conduction losses, as well as low switching losses. To address these challenging requirements, onsemi has developed the SUPERFET® family of super-junction (SJ) MOSFETs with best-in-class figures of merit and capable of supporting extreme dVDS/dt ratings.

The one thing about using MOSFETs is they require a gate driver. Gate drivers are solid-state devices optimized to efficiently and reliably drive the large input gate capacitance on MOSFETS. Ideal gate drivers minimize switching losses in the MOSFET while also providing robust over voltage/over current protection for those same inputs.

onsemi has developed a low-cost gate driver specifically targeted for battery chargers where the bill of material (BOM) needs to be minimized. The NCD83591, a three-phase gate driver, has the following properties:

Other components available from onsemi for use in battery chargers include SiC diodes (for rectification), controllers (for power management) and current sensors (for protection).

For battery management and power tree, onsemi offers a wide selection of regulators as well as a low voltage temperature sensor. With respect to regulators for the power tree, onsemi offers both DC/DC regulators and linear regulators (LDOs).

The DC/DC components are synchronous buck regulators that operate up to 65 V. The linear regulators are low noise and operate up to 1 A.

The NCP730 CMOS LDO regulator can support up to 38 V input voltage and 150 mA output current. The NCP730 provides ultra−low quiescent current of only 1 uA, which makes this device the ideal solution for battery-powered application. Output voltage can be set from 1.2 to 24 V, adjustable or fixed.

Similar to battery chargers, motor drivers also require MOSFET switches. To operate a BDC motor bi-directionally requires two half bridges with two MOSFETs each. To drive a 3-phase BLDC motor requires three half bridges with two MOSFETs each.

To address these applications, onsemi offers a large portfolio of low voltage-medium voltage (LV-MV) MOSFETs including the new T10 PowerTrench® family for power applications. The T10 MOSFETs achieve higher power density, reduced switching losses, reduced overshoot/noise and higher reliability than previous generations. Each of these MOSFETs requires a gate driver and the gate driver NCD83591 mentioned previously works here as well.

Other components available from onsemi for use in the motion subsystem include motor drivers, rotary position sensors and operational amplifiers.

MOSFETs and low voltage devices like controllers need to be protected. However, each requires different types of protection. In general, MOSFETs need thermal and over voltage protection, whereas low voltage devices require protection against ESD.

MOSFETs can be protected by gate drivers, which protect against over voltage and over current on the gate. They can also be protected against over voltage by diodes on the gate and drain. onsemi offers a wide variety of gate drivers (including the low-cost NCD83591 mentioned previously) as well as protection diodes like Zeners and Schottkys.

Other considerations in support of power protection include:

The market for battery-powered tools is large and continues to expand. Its continuous and accelerated growth is due, at least in part, to the improvement in the components and subsystems that comprise the cordless tools.

The three main subsystems are the battery charger, the battery/power tree and the motion. Each of these subsystems is designed around application-specific semiconductor components.

onsemi has a complete portfolio of devices specifically targeting the cordless tool market. It includes a wide range of low-cost, highly efficient, reliable, small form factor semiconductor components. From high-power MOSFETS and SiC diodes to low-power controllers and sensors, onsemi is the best place to start your battery-powered tool design or upgrade.

To learn more about onsemi’s offerings in this area, including specific parts/part numbers, request your copy of our Battery-Powered Tools System Solution Guide.